Interviewee

Mr. Moriaki Shibata, section manager, CS Promotion Department Center Management Group

Mr. Shouki Ono, Customer Satisfaction Promotion Department Kansai Region Customer Center

Manufactures,developers, and infrastructures involved in businesses for customers' safety and daily lives.

Those who consider combining their offices and contact centers

Build BCP Systems for Maintaining its Services under Emergencies

Quality Maintenance in Multi-site Operations

Contact Center

Reception for Inquiries and Repair Inspections from Owners

Notifications of Regular Maintenance

BPO

Requests for Repair Form Creation

BCP system establishment and operation with Three Centers

Operational recovery in afflicted areas subsidized by other centers within 20 minutes after the Great East Japan Earthquake.

Achieved a high response rate of over 90% even in emergencies such as earthquakes

Mr. Moriaki Shibata, section manager, CS Promotion Department Center Management Group

Mr. Shouki Ono, Customer Satisfaction Promotion Department Kansai Region Customer Center

The year 2005, when the customer center was established, was a major milestone for Daiwa, marking the 50th anniversary of its founding. In addition to formulating a new management vision and employee charter, the “Endless Heart” was established as the Group's logo, and “Creating Together, Living Together” became its basic stance, expressing our desire to maintain a lifelong relationship with our customers. “We have the term ‘Individual Customer Mindset.’ We treat each customer as an individual and align our thinking with them. We launched our customer center to provide tailored after-sales service. Until then, each branch office had been handling customer inquiries and repair requests from customers separately, and this was the first time we had established a contact center. We requested proposals from several contact center operators, and as a result, we selected BELLSYSTEM24,” said Mr. Shibata.

Why was BELLSYSTEM24 chosen?

“It was because their proposal was one or two steps ahead of those of other companies,"" said Mr Shibata. ""They had thoroughly studied our business and had prepared their proposal to meet our needs. We had high expectations that they would be able to understand what we were thinking, and we had high expectations that we could work together with them to manage the center with the 'Individual Customer Mindset'.""

The reason why we initially dared to set up multiple customer centers was that we expected that the nature of customer inquiries would varie depending on the area. After that, triggered by the establishment of a BCP committee within Daiwa, we created a manual on the BCP system at the CS Promotion Department, which oversees customer centers. We initiated efforts to quickly normalize center operations even in the event of an emergency.

It was during the Great East Japan Earthquake that we realized the results. The first major quake, which began at 14:46 on March 11, 2011, even reached Osaka. “We were on the 20th floor of the head office in Osaka, and we felt a tremendous horizontal shaking. The situation inside the customer center in Sendai was such that PCs were overturned,” said Mr. Shibata.

Despite such a situation, inquiries from customers on the Sea of Japan side of the Tohoku region, which suffered less damage, continued to reach our East Japan Customer Center in Sendai. The center immediately decided to switch to BCP response, and by 3:06 p.m., 20 minutes after the first major quake, our Kansai and West Japan Customer Centers were ready to handle calls from the Tohoku region.

During the subsequent COVID-19 pandemic, when our customer centers in the Kansai region were temporarily closed, the response rate of 98.8% was maintained by the backup from our East and West Japan Customer Centers. Also when a major earthquake hit Tohoku in March 2022, the response rate reached 93.6%.

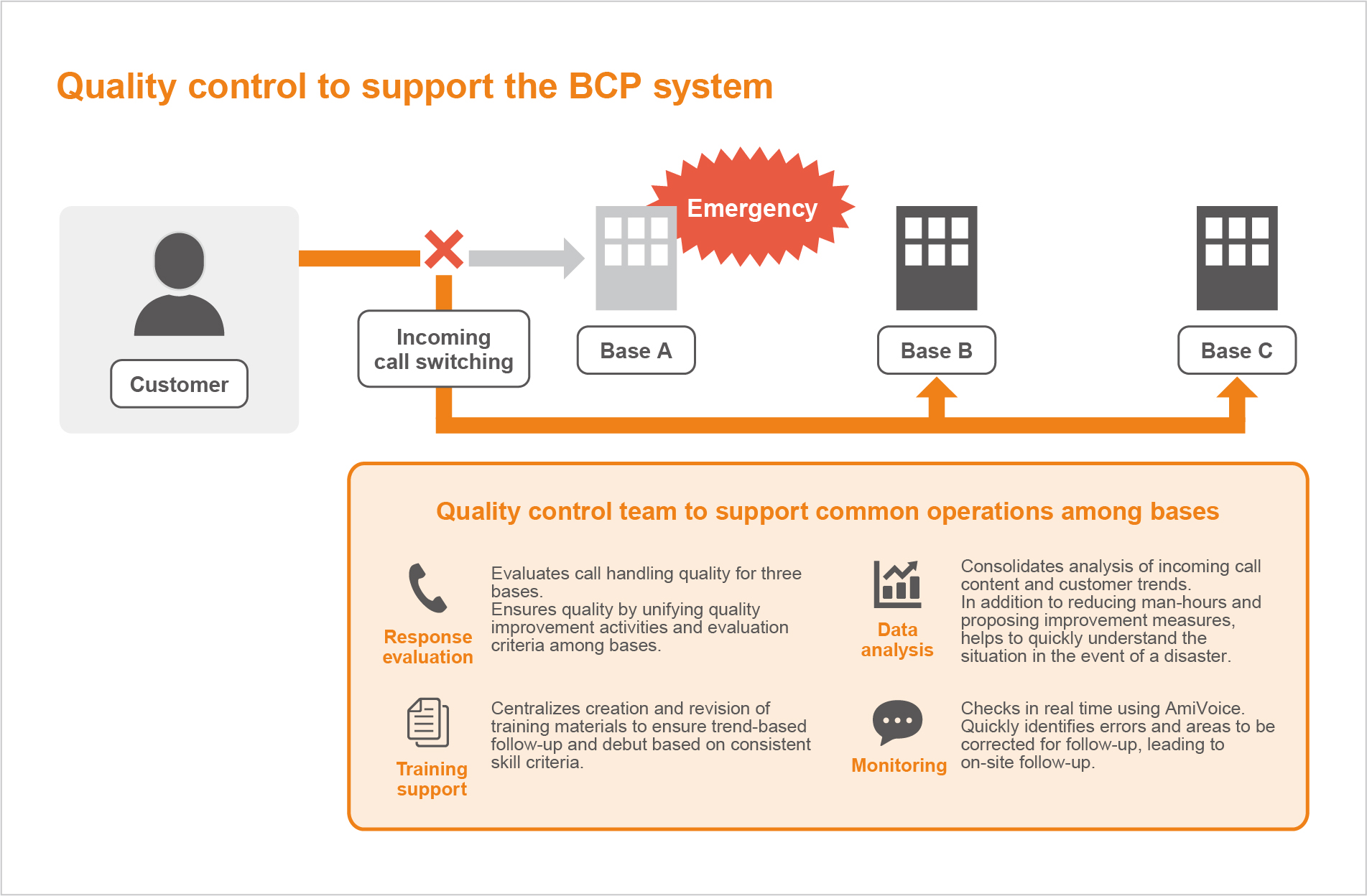

In general, when multiple centers are deployed, each center has its own rules and regulations, so it is said that even if a BCP system is established, it tends to have variation in operation and quality.

BELLSYSTEM24 identified tasks that could only be performed inside the center and those that could be performed outside the center, and consolidated tasks such as response evaluation, incoming call content and customer trend analysis into the quality control team. In addition, the fact that BELLSYSTEM24 as a single company operates our customer center enables seamless operation between centers and builds a BCP system that allows for quick changeovers.

There are four main activities performed by the quality control team that support the BCP system. The first is the evaluation of call handling quality at the three bases. We also provide monthly feedback to all bases and training to managers to standardize the evaluation criteria to eliminate discrepancies and ensure quality by eliminating gaps. The second is support for training new employees. By consolidating the preparation of materials from training to debut, we can provide unified knowledge and skills and individualized follow-up, leading to retention. The third is data analysis. We collect and analyze incoming call data from all bases and share countermeasures with all centers, enabling a quick understanding of the situation in the event of a disaster. The last is the use of voice recognition technology. “AmiVoice,” a solution that automatically converts voice data into text, is being used to reduce errors and improve efficiency. Instead of the conventional “listening to voice,” voice data is converted into text, and “visual confirmation” makes it easier to understand each operator’s habits, enabling more efficient individualized follow-up.

During a disaster, the content of inquiries to the contact center will change over time. “When the Great East Japan Earthquake disrupted power and other lifelines, we initially received many inquiries such as, ‘The storage batteries are not supplying power,’ and ‘The refrigerators have stopped,’” said Mr. Ono. “After that, the content of customers’ inquiries changed over time, such as, ‘I requested an inspection, but I haven’t heard back yet,’ and “When will I be able to receive normal service again?” Mr. Shibata continued.

“Even in such an emergency, BELLSYSTEM24 calmly offers ideas to improve the current situation and makes proactive suggestions such as, ‘Looking at the current situation, there may be more inquiries like this next time, so could you think about how to respond?,’ Our customer center would no longer be possible without BELLSYSTEM24,” said Mr. Shibata.

The company is considering the possibility of using multiple bases to respond to customers nationwide in the future not only in times of disaster but also during normal times, and various other initiatives are also underway. "Some of the inquiries we receive from our customers are about problems they can easily solve by themselves. While being asked to minimize human contact as much as possible due to the COVID-19 pandemic, we have initiated a measure called “Call Assist.” By sending short emails to our customers with URLs of self-repair guide videos, we have empowered them to do repairs by themselves, saving them time waiting for repairs," said Mr. Shibata.

In addition, plans for digitization and paperless operations to improve operational efficiency have already begun. “We would like to become a true cooperative partner, not only by improving efficiency but also by standardizing other tasks that can be standardized and then extracting them to outsource to BELLSYSTEM24,” said Mr. Shibata.

DAIWA HOUSE INDUSTRY CO., LTD.

Corporate website:https://www.daiwahouse.co.jp/

Established in April 1955. Engages in a wide range of construction businesses, from custom-built detached and for-sale housing to condominiums, commercial facilities, and medical facilities, as well as urban development and green energy businesses. Capital: 161,699,201,496 yen, Sales: 1,976,165 million yen (as of March 2022), Employees: 16,535 (as of April 2022).